debris flow

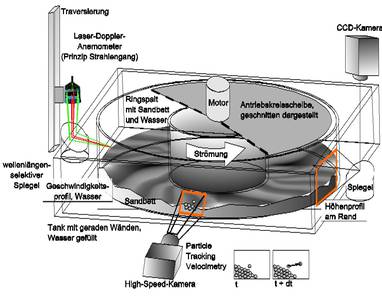

This set-up forces a debris flow at the groung of the cylinder. Additionally the interface between debris and liquid media is destabilized. The new steady shifting form depends on debris material and the mean shear stress at the surface of the granular bed. Inside the debris flow cylinder a steady shear flow controled by a rotating disk is built up. The shear stress inside the layer between forcing “upper wall” and the granular bed induces interaction forces between the moved fluid and the solid particles at the ground.

Analysing the structure forming of granular media the interaction between the particles and the surrounding fluid follows the generation procedure of periodic flow structures near the granular bed surface. The unsteady behavior of the boundary layer flow forces a deformation of the bed surface.

Modeling fluid flow and granular motion is made with continuum mechanical transport equations. The granular media are moved by the shear stress attaching at the bed surface. The motion is comparable with the shear motion of continuous media. The particle diffusion works similar to the deformation of a non-newtonian, incompressible fluid. Because of the interaction forces at the interface the granular bed surface is deformed and holds the structure also after stopping the flow, because of the plastic components of the modeled material properties of the quasi-continuous dispersed medium.

"

"