hybrid engines

In contrast to liquid and solid rocket engines, where both components are either liquid or solid respectively, the oxidiser and propellant in hybird engines are separated by phase. In most cases the latter is solid while the former is liquid or gaseous (classical hybrid), but reverse hybrids where also successfully tested.

This unique combination leads to many advantages compared to other rocket propulsion systems:

Safety - Since the propellant and oxidiser are separated by phase an intimate mixture of the two components is not easily obtained and the possibility of catastrophic explosions is significantly reduced (when using non-hypergolic components).

Simplicity - Compared to liquid bipropellant systems the amount of fluid management systems is reduced by a factor of two, since only one liquid (oxidiser) has to be carried into the combustion chamber. Also, when using the right propellant combination the ground handling of the engine is simplified, since the propellants are benign.

Specific impulse - Hybrid rockets can achieve very high specific impulse. Even if the choice of propellants is reduced substances that a non-toxic, non-explosive and easy to handle, a specific impulse midway between solid- and liquid propulsion systems can be achieved.

Controllability - In contrast to solid rocket engines, hybrids can be throttled and shut down easily at any stage of the flight. The throttling range however is lower than that of a liquid propellant system.

Wide range of propellants - There are many propellant choices for hybrid rockets, which opens many possible applications from green propellants to waste incineration with propulsive effect on board of the international space station.

These advantages come at a cost of some disadvantages:

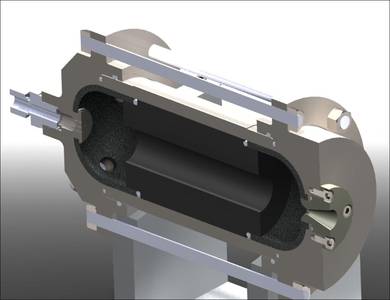

Diffusion limited combustion - The combustion in a hybrid rocket engine is limited by the diffusion of the evaporated solid propellant through the boundary layer into the flame zone, where it mixes with oxidiser stream in the port and combusts. This phenomenon causes two problems, first a limited mixing which can be mitigated via an aft combustion chamber, and second (and more importantly) a fairly large surface area is required since the regression rate of the fuel is low.

Low volumetric efficiency - The above mentioned low regression rate, requires large surface areas for engines with high thrust. This in turn makes the engines rather bulky compared to liquid propulsion systems.

There are however means to overcome these disadvantages, which range from the right propellant choice with a high regression rate (for example through liquefaction and droplet entrainment) , to adapted injector designs and fuel grain modifications.

In addition to these many technological advances in other propulsion oriented sectors have never been applied to hybrids. This means there is a high potential for innovation and improvement. The main goal of the research in the area is to provide a holistic approach to the entire hybrid engine and to compile and improve on all the basics needed to design an engine that is optimally suited to the application at hand.

One step in that direction is the participation in the STERN (Student Exprimental Rockets) Project, sponsored by the DLR. The ZARM contribution to this project will be the ZEpHyR (ZARM Experimental Hybrid Rocket) that will fly to an altitude of about 20km from the Kiruna (SSC Spaceport) using a hybrid rocket engine.

"

"